Investing in Interns:

Building Your Future Workforce

In today’s manufacturing landscape, finding and retaining skilled talent is one of the greatest challenges facing employers. As experienced workers retire and competition for the next generation of employees heats up, many Hudson Valley manufacturers are turning to an often underutilized strategy: internships.

Internships are far more than a short-term solution to a summer staffing shortage. For manufacturers who take the time to structure thoughtful, engaging programs, they can be the start of something much bigger. They create opportunities to build relationships with promising students, introduce them to rewarding careers in manufacturing and develop the skills and knowledge your workforce needs to thrive. In many cases, today’s intern becomes tomorrow’s full-time hire—and potentially a key part of your team for years to come.

Manufacturers like IBM, Zierick Manufacturing, Sono-Tek, JBT and UAP have seen firsthand the difference a successful internship program can make. Whether they’re partnering with local high schools and colleges, offering hands-on learning experiences in advanced manufacturing, or supporting interns as they balance work and education, these companies understand that internships are an investment in their future workforce.

Success comes from being intentional, flexible and willing to invest time upfront.

Even as this year’s class of interns is already gearing up for summer opportunities or preparing to graduate, now is the perfect time to plan or expand your future internship program. In this article, we’ll explore what makes a successful internship, share lessons learned from companies who are doing it right and highlight how manufacturers across the Hudson Valley are building their talent pipelines—one intern at a time.

Lessons from the Factory Floor

Internships aren’t one-size-fits-all, and there’s no universal playbook for getting them right. A program at Central Hudson or IBM—will naturally look different from the experience a small- to mid-sized manufacturer can offer. But that doesn’t make it any less valuable.

In fact, many Hudson Valley manufacturers have found that a smaller, more personalized internship can have an even greater impact. With fewer layers and more direct access to leadership, interns often get a broader view of the business, more hands-on experience, and a stronger sense of how their work makes a difference.

Whether they bring on one intern a year or several each season, manufacturers who have made internships part of their workforce strategy share a common theme: success comes from being intentional, flexible, and willing to invest time upfront. The result? Interns who add real value to the business—and often return as long-term employees.

Start Early—and Plan with Purpose

The best internship programs don’t happen by accident. They’re the result of thoughtful planning, clear expectations and early action.

At Zierick Manufacturing, planning for interns begins months in advance. “We identify projects ahead of time and map out where each intern will rotate or focus,” says Joe Turcott, Vice President and CFO. “This makes the experience more meaningful for everyone.” Zierick finalizes internship placements by April, ensuring there’s time to prepare meaningful work and proper support.

At IBM Poughkeepsie, Supply Chain Engineering and Manufacturing internship planning begins with an assessment of business needs. “We work closely with managers and technical leads to identify teams that would benefit from the additional talent of an intern, with the aim of converting successful interns into full time IBMers after graduation, says John Maresca, Program Director, SC Global Business Operations. “Our goal is to provide meaningful projects tailored to the strengths and interests of the selected intern.”

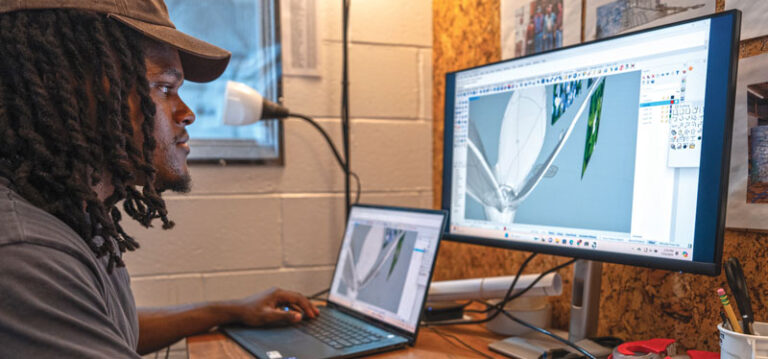

At UAP, internships are crafted with the same level of care as their art manufacturing projects. Gilbert Guaring, Global Head of Marketing, explains that his team reviews each intern’s background and interests before choreographing a rotating schedule that aligns with their skills and goals.

“It’s about building relationships early, by the time we’re ready to recruit in the second semester, students already know who we are and what we offer.”

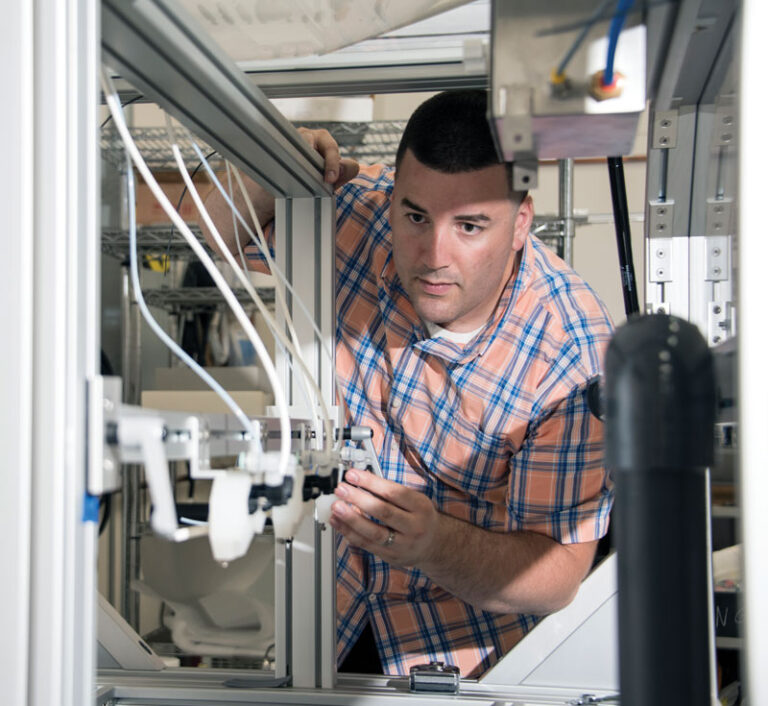

Provide Real-World, Hands-On Experience

Students are looking for internships that will teach them something valuable, not just fill time. Companies that offer meaningful hands-on experiences see better engagement—and better results.

At Sono-Tek, interns are placed based on both the company’s needs and the students’ interests. “We focus on providing meaningful, hands-on experiences,” says Randy Copeman, Chief Technologist, Sono-Tek. “Never internships just for the sake of having them.” Interns are paired with department mentors and management mentors, working side by side with full-time employees.

John Nolis, Operations Manager at JBT says internship rotation offers a 360-degree view of their operations. Interns spend time in field service, engineering, inventory and operations. “We want them to understand how everything works together—and why,” says Nolis. By experiencing different parts of the company, interns get a broad education and discover where they can make the biggest impact.

At UAP, interns shadow expert team members in departments like Sand Molding and Finishing. Guaring recalls a young sculptor who became enthralled with sand molding techniques during his rotation. “He told us he wants to come back and work in that area after graduation,” Guaring says. “That’s what we hope for—to inspire them to see a future here.”

Provide Mentorship and Clear Expectations

The best internships balance support with accountability. Interns need guidance to succeed—but they also need to understand what’s expected of them.

Zierick looks for interns with strong communication skills, good attendance, and a willingness to learn. “One of the biggest things we’ve noticed is that interns often hesitate to ask for help,” says Turcott. “We try to create an environment where they feel comfortable speaking up, but we also make it clear they need to meet our expectations.”

At Sono-Tek, each intern is paired with mentors who provide both technical and personal support. The company’s structured training programs ensure interns are set up for success from day one. “It’s about giving them the tools to succeed, but also the responsibility to perform,” says Copeman.

UAP treats interns like regular employees, with full onboarding and safety training. “We want to inspire the next generation, but they have to bring dedication, curiosity and courage,” says Guaring. “This is real work and we treat it that way.”

Build Long-Term Relationships, Not One-Off Experiences

The most successful internship programs are pipelines, not pit stops. Many Hudson Valley manufacturers view their interns as future employees—and they cultivate relationships accordingly.

Zierick Manufacturing often hires interns back during holidays and summer breaks, supporting them as they pursue two- and four-year degrees. JBT has a track record of retaining interns from SUNY Delhi, with 11 interns hired over the last decade—and none have left. “They’re critical to our organization,” says Nolis. “They become instrumental in what we do.”

“Joe Scaglione’s journey with IBM began in high school, interning at our Poughkeepsie manufacturing facility,” says Maresca. “He completed four summer internships while studying engineering at RPI, gaining hands-on experience across teams. Today, he’s a key part of our Manufacturing Engineering team. His success is a testament to what’s possible when we invest early in future talent.”

For many employers, the idea of starting these relationships can feel daunting—but it doesn’t have to be. Building connections with schools, colleges, and potential interns doesn’t require a huge investment of time or resources. In fact, many manufacturers build direct relationships with educators, guidance counselors and workforce programs to connect with students and promote career opportunities. Teachers and career counselors are often eager to work with industry partners; they just don’t always know how to make the first connection but as more employers open their doors to interns, high schools and colleges are responding by building the infrastructure and support needed to expand experiential learning. Schools like Ulster BOCES and SUNY have prioritized these efforts, with Chancellor John B. King, Jr. stating, “Internships and hands-on learning experiences are essential to prepare students for success after graduation. We are committed to expanding these opportunities across the SUNY system.”

National Trends Confirm What Local Manufacturers Have Learned

The value of internships isn’t just anecdotal—national data backs up what Hudson Valley manufacturers see every day. Internships continue to prove their value as an effective way to build a future workforce. According to the National Association of Colleges and Employers (NACE), 53% of interns were converted into full-time hires during the 2022–2023 period. While this is a slight dip from 58% the previous year—largely due to fewer offers being extended—the data underscores the critical role internships play in workforce development. Nearly 80% of employers also reported plans to maintain or increase their internship and co-op programs, reflecting a broad commitment as a strategic tool for recruiting and hiring the next generation of talent.

Here in the Hudson Valley, manufacturers are seeing similar results. Companies report better retention, smoother onboarding and stronger cultural fit among former interns who transition into full-time roles. Gilbert Guaring of UAP says their interns often envision long-term careers with the company. “By fostering a sense of belonging and providing hands-on experiences, we’re building future employees,” he explains.

A Long-Term Investment Worth Making

Hudson Valley manufacturers know that building a strong workforce doesn’t happen by chance. It takes a willingness to invest in the next generation. Internships offer a proven, practical way to do just that—providing students with meaningful experiences while helping companies develop future talent.

For manufacturers already engaged in internship programs, the payoff is clear: interns become trusted employees, ambassadors for the industry and often long-term contributors to their companies’ success. Internships also allow both employers and students to assess cultural fit before making long-term decisions. When interns return during school breaks or accept full-time positions after graduation, companies save time and money on recruiting, onboarding and training. And by bringing in fresh ideas, updated skills and new perspectives from the classroom, interns can energize teams and add real value across the organization.

The next generation of skilled, dedicated manufacturing talent is already here.

For those just beginning to explore internships, there are simple ways to get started—whether it’s attending a career expo, reaching out to a local school or partnering with the Council of Industry.

These relationships don’t need to be complicated or time-consuming, but they do require attention. The good news? Once those connections are made, they’re often easy to maintain, and the long-term benefits far outweigh the effort.

As today’s manufacturing landscape continues to evolve, it’s the companies that invest in people—whether through internships, apprenticeships or training programs—that will build the strongest teams for tomorrow. The next generation of skilled, dedicated manufacturing talent is already here. The question is: will they find a future with you?