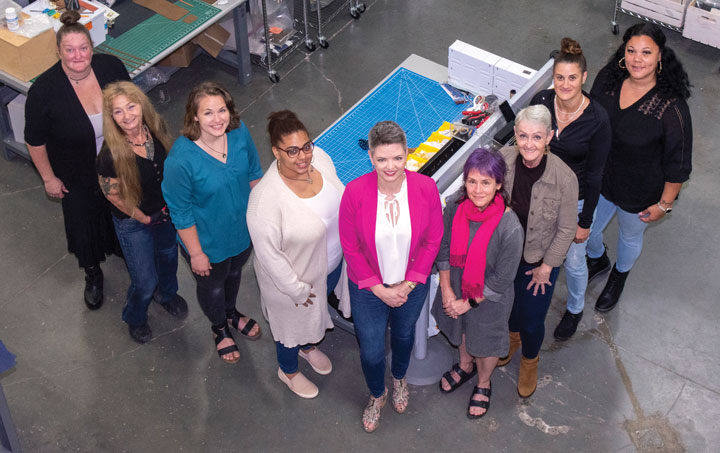

Leading With Purpose Kelly Lyndgaard and the Women of Unshattered

HV Mfg sat down with Kelly Lyndgaard, founder and CEO of Unshattered, a 501(c)3 social enterprise organization. Unshattered provides second-chance employment opportunities for women who have experienced addiction and come out the other side. Unshattered believes that a pathway to economic recovery is just as essential as the physical and psychological healing from addiction. By providing employment and job skills training in a community of like-minded women and continued dedication to ongoing personal and professional development, they see women remain sober and reach their full potential.

HV Mfg: Thank you for talking with us. Let’s start with the basics – tell us about Unshattered.

KL: Thank you for the opportunity! Unshattered is in the business of second chances. We are a not-for-profit social enterprise that manufactures premium handbags. Our mission is to ‘end the addiction relapse cycle by providing pathways toward economic independence and sustained sobriety.’

We hire women who are overcoming extremely difficult circumstances. All are overcoming addiction – but that addiction is only part of their stories. They have also experienced some combination of trafficking, abandonment, abuse, and incarceration. And, we teach them a wide range of skills to produce the bags, from pattern making and sewing to marketing, production, and leadership.

Being a social enterprise we have a double bottom line. One is to produce products people will buy at a price that sustains the organization. The second is to provide growth and development for the women who work here – to show them there is a world of opportunity for them and that there are resources available to help them be successful.

HV Mfg: We understand you are an engineer by training. Tell us about your journey from that profession to this one.

KL: I am an engineer by training. I grew up in Pennsylvania and went to college in Indiana at Taylor University where I studied engineering and physics. When I graduated, I went to work for IBM in Rochester, Minnesota. I loved it.

During my career, I worked on a series of projects including Blue Gene/P (which, at the time in 2008, was the world’s fastest supercomputer), and strategy and M&A for IBM’s Systems division. My last role was as an executive leading database product management for DB2 and Informix. Also during my time at IBM I met my future husband and moved to the Hudson Valley.

HV Mfg: That is an impressive start with Big Blue. It sounds like you were on track to a senior-level position. What changed?

KL: Thank you – it was exciting and I loved my career there. What changed was, one Sunday I heard a woman who was recovering from addiction speak at our church. I was raised to believe that if you work hard and behave you will be rewarded. I was pretty sure that the solution to addiction is to – you know – ‘stop sticking a needle in your arm’ and ‘get a job’.” But this woman’s story challenged my preconceived ideas.

Emily grew up with a single mom who was frequently sick and at 8 years old she was already helping to care for her mother and siblings. A 15-year-old neighbor thought it would be ‘funny’ to watch an 8-year-old get high. Her life quickly fell apart. Addiction and homelessness followed. Hearing her story hit me like a ton of bricks. How can I, or anyone else, hold someone accountable for their irresponsibility when their addiction began when they were just a child?

I started to do some research – I do have that engineering training you know and am a problem solver by nature – and I learned a lot about addiction and about the people who struggle with substance abuse. One thing I learned is how extremely difficult it is for people to maintain their sobriety for the long term. What a challenge it is for them to leave a year-long recovery program and then reenter the same environment where their addiction started.

During my research, I was introduced to an amazing local 365-day residential recovery program. I met women who were working so hard to overcome their addictions – to understand and tackle its underlying causes. I was amazed by their strength. I wanted to help.

I am also a crafter and a ‘maker’ and a few years earlier I had made a bag out of my grandfather’s coat as a way to remember him. It occurred to me that if I could teach the women to make bags out of recycled materials, the way I had, perhaps they would also find it rewarding and therapeutic.

I was unprepared for the impact of making something beautiful, and having someone pick it up and admire it, would have on these women. How something lit up inside them. They were radiant. I could see the power being creative offers. We set up a workshop and started a project making bags out of upcycled materials.

Doing this during treatment was certainly helpful, but it wasn’t enough. Recovery programs do amazing work helping people get to sobriety, but they don’t address what I call the “Day 366 problem.” There is a gap between getting sober, and maintaining sobriety for the long term. It started to become obvious that women without education, job skills, or a safe community to return to after recovery, were at huge risk of relapse and death.

At first, I thought that helping them get good employment was the solution. We added a 6-month internship, offering the women a good reference. But, the reality was we were not solving the problem of a safe community to go back to. At the time, I was still in my executive role with IBM and I was conscious that the bag-making enterprise was growing. We were selling more bags, and the work was getting more sophisticated.

HV Mfg: So, you just quit your day job?

KL: Pretty much, yes. I quit my day job.

HV Mfg: That took some courage.

KL: Honestly, at that point it would have taken more courage not to. I really felt compelled to help. And, for all the trappings of the corporate world, for all the rewards it was offering, I just knew this was where I belonged.

HV Mfg: Let’s talk about the business side of the model. How do you balance the craftmanship and customization these beautiful high-end bags require with the need for efficiency?

KL: That really is a challenge and kind of where our “double bottom lines” come together. On the one hand, we are seeking efficiencies to be economically healthy and sustain our operations. On the other hand, it is important that the person making the bag has ownership of it – that it is hers – and that we prioritize the employee’s long-term success. We are always working to find some efficiencies, but when those two things collide we will choose the individual’s development and ownership every time.

HV Mfg: With that in mind, tell us about the “secrets” in each bag?

KL: As I mentioned, all our bags are handcrafted from something discarded. The bags represent second chances for both our materials and the women who work with them. Each one also contains three secrets unique to that particular bag. Secret one is the we hide a message written in the inside of the liner from the woman who made it. The message is something meaningful to her; perhaps a verse, her number of days of sobriety, or a blessing for the future owner.

Second, the bags are named for people who are still struggling with addiction. We receive names from organizations like She Has A Name and Faces of Change in Camden, NJ, which work with individuals still on the streets. We let our customers know they are carrying their bag in honor of someone we hope finds healing, just like the women on our team have.

Finally, we include a gold seam sewn into each bag. This is a nod to Kintsugi which is a Japanese art form that takes broken pottery and repairs it with a gold lacquer. Its point is to show that breakage and repair are just part of life – it highlights and emphasizes imperfections. I think this is a perfect allegory for what we do here at Unshattered.

HV Mfg: Talk about the shifts you are seeing in the fashion industry and how you are adjusting to meet them.

KL: I’m seeing in our industry the same trends shaping the economy as a whole. And a lot of those work to our advantage. Organizations and the people who work for them, as well as customers, are putting an emphasis on environmental sustainability. They want products that are built to last and do minimal harm to the environment.

At Unshattered our bags are made from repurposed materials. Some of our most popular bags come from repurposed leather donated by Southwest Airlines from the seats on their planes. We also make bags from West Point cadet uniforms that are donated when they graduate.

A part of the focus includes energy sustainability. As you can see, we are in the process of renovating this building and will be emphasizing energy efficiency and renewables. We are working with Mass Design in Poughkeepsie to ensure that our building is highly efficient. It is also part of the ‘Design for Freedom’ movement led by Grace Farms. That movement seeks to ensure that all the materials used in construction are free of any forced labor in their supply chains.

From a pure fashion point of view, because we are such a small shop and do so much customized work we believe we are nimble enough to adjust quickly to any changes in customer tastes.

HV Mfg: How many women are working at Unshattered today?

KL: We have 12 women working here. The goal is to have as many as 50 in five years and we have already added two since May 1st of this year. This new facility will allow us to expand our operation. The demand for the product is there. People appreciate our mission. But, they also appreciate the quality and the beauty of the bags we are making.

It’s also true that there are many women out there who would greatly benefit by being a part of Unshattered. There is a tremendous need and I think we can – over the next three to five years – grow the business enough to need that many employees.

HV Mfg: How would you describe your leadership style? Have you had to adjust it to be successful here?

KL: I describe myself as a strategist. I am pretty good at organizing complex situations, setting goals and putting together plans to get to the desired outcomes. That has served me well so far here at Unshattered. Starting an organization from scratch, identifying the “double bottom line” to produce products to support the organization while also providing growth and development for the women who work here, has proven pretty complex. But, I think I am meeting that challenge.

I like to think that I am always evolving as a leader and always trying to hold myself accountable – the same way I hold others accountable. We use a “Balanced Scorecard” model for me – and Unshattered.

HV Mfg: Tell us more about that – What does a Balance Scorecard look like here?

KL: A Balanced Scorecard model is basically a holistic system for managing strategy when an organization has competing priorities. It provides a framework that gives organizations a way to “connect the dots” between the various components of strategic planning and management. Even though we are relatively small, we are fairly complex and the model gives us a visible connection between the projects and programs that we are working on. It also gives us the key performance indicators we need to measure our progress and success.

HV Mfg: We know you have worked to cultivate partnerships to support the organization. You mentioned Southwest Airlines – who are some of the others?

KL: There are so many! Yes, I mentioned Southwest Airlines and we are very proud to be part of their “Repurpose with a Purpose” program. I also mentioned Mass Design. They have been great in helping us with the renovation of this building.

I also want to mention Ten Yards, global experts in fashion production and supply chains. They have been really instrumental in getting our production up to where it needs to be. They have helped with the layout of our operation, making sure our workstations and equipment are effectively deployed. They understand our double bottom lines and have really helped us achieve them.

Marist has also been an incredible partner and our relationship is mutually beneficial. Their professors and staff have generously contributed their expertise, opened up their classrooms to focus student projects on our work, and introduced us to incredible industry partners.

Marist prioritizes community impact and real-work student experiences. And, this generation of students is committed to social impact through their work. We’re giving students the opportunity to truly influence a growing organization and show them that it’s possible to use business for good.

And of course, we appreciate the support the Council of Industry has given us. In particular we appreciate your leadership development program. A handful of our women have participated in the training and it really has been transformative for some of them.

Part of our role is to instill confidence in these women. The Certificate in Manufacturing Leadership helps them better understand themselves and how they relate to others and gives them valuable problem solving and communication skills. A few will be participating in your Lean Six Sigma training this fall too. All of it helps build confidence, and just as important, helps us be a more effective and efficient operation.

HV Mfg: We are very proud to support Unshattered in both its bottom lines. Thank you for all you do and for taking some time to speak with us today.

KL: Thank you – I appreciate the opportunity to share our story with your readers.