Artificial Intelligence in Manufacturing: Unleashing the next industrial revolution

Editor’s note: We hear a lot about Artificial Intelligence and its impact on various industries. In seeking an expert to write on the subject it occurred to us to go right to the source – so we asked ChatGPT to “Write a 1200-1500 word article for the Council of Industry HV MFG magazine about the future of artificial intelligence in the manufacturing sector.” Below is the result. While we see some holes, and some things we would have done differently, we believe it is, on the whole, pretty good.

Tell us what you think.

The manufacturing sector has long been a hotbed of innovation, driving economies, and shaping societies. Today, the industry stands at the precipice of an unprecedented transformation, poised to embark on the next industrial revolution powered by Artificial Intelligence (AI). In this deep-dive article, we explore the intricate facets of AI’s future in manufacturing, examining how it’s revolutionizing everything from design and production to workforce dynamics and sustainability.

Smart Factories: Where AI Meets the Production Line

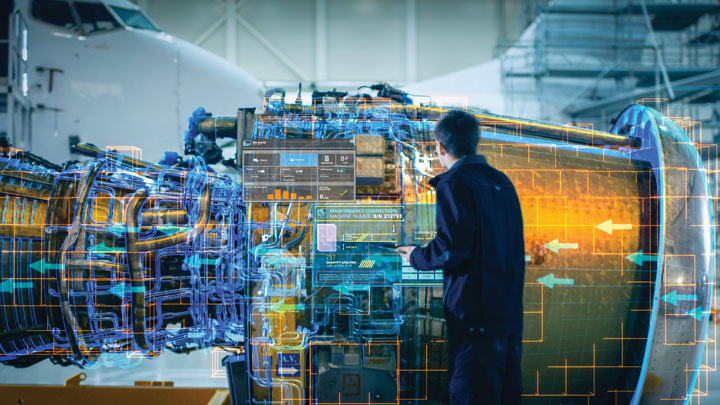

Real-Time Optimization: Smart factories represent the pinnacle of AI integration in manufacturing. These high-tech hubs leverage AI, the Internet of Things (IoT), and data analytics to create highly connected and responsive production environments. Machines, processes, and systems communicate seamlessly, enabling real-time optimization. Production lines adjust settings autonomously based on real-time data, ensuring peak performance around the clock.

→ Case Study: Bosch’s Industry 4.0: Bosch has embraced the concept of Industry 4.0, transforming its manufacturing facilities into smart factories. AI-driven data analysis optimizes production processes, reducing energy consumption by up to 15% and maintenance costs by 30%.

Predictive Maintenance: Predictive maintenance is a game-changer. AI algorithms analyze data from sensors and machinery to forecast equipment failures. Maintenance schedules are adjusted proactively, minimizing downtime and maximizing productivity.

→ Case Study: Siemens’ Predictive Maintenance: Siemens employs AI-powered predictive maintenance in its factories. By accurately predicting machine failures, they’ve achieved a 10-20% reduction in downtime and a 20-30% decrease in maintenance costs.

Resource Efficiency: Sustainability is a driving force in manufacturing today, and AI plays a vital role in achieving it. AI fine-tunes processes to reduce waste, lower energy consumption, and decrease the environmental footprint.

→ Case Study: Toyota’s Sustainable Manufacturing: Toyota has integrated AI and automation into its manufacturing processes, reducing carbon emissions by 15% and water usage by 40%. They’re also aiming for zero waste to landfill.

Quality Assurance: AI-driven quality control systems are redefining quality assurance. Computer vision and machine learning algorithms inspect products with unmatched precision, reducing waste and ensuring superior product quality.

→ Case Study: Foxconn’s Automated Inspection: Foxconn, known for manufacturing Apple products, uses AI-powered robots for product inspection. This has improved accuracy and reduced errors by 30%.

The manufacturing industry’s future is unfolding today, and it’s nothing short of a thrilling revolution.

AI-Enhanced Design and Prototyping:

A Creative Resurgence

Generative Design: The design phase is undergoing a revolution thanks to AI. Generative design algorithms explore countless design variations, optimizing for factors like strength, weight, and cost. This not only speeds up product development but also results in innovative designs that human engineers might not conceive.

→ Case Study: Airbus’ Bionic Partition: Airbus used generative design to create a bionic partition that was 45% lighter and reduced CO2 emissions by 66% compared to conventional designs.

Simulation and Prototyping: AI simulates product performance under various conditions, reducing the need for physical prototypes. This not only saves time and resources but also allows for more accurate and reliable product testing.

→ Case Study: GE’s Jet Engine Design: GE used AI simulations to optimize the design of a jet engine components, reducing weight by 10% and increasing fuel efficiency.

Customization and Personalization: Consumer demand for customized products is growing. AI-driven manufacturing systems can efficiently produce customized products in small batches. By analyzing customer data and preferences, AI guides the production process, enabling personalized products at scale.

→ Case Study: Adidas’ Custom Shoes: Adidas offers custom shoes through its Speedfactory. AI-driven design and production allow customers to personalize their shoes, resulting in higher customer satisfaction and loyalty.

AI serves as a valuable decision support tool for human workers. Workers can make more informed choices, ultimately driving efficiency and productivity.

Human-AI Interaction and Workforce Development:

A New Collaborative Era

Collaborative Robots (Cobots): AI is not supplanting human workers; it is enhancing their capabilities. Collaborative robots, or cobots, work alongside humans safely, handling repetitive and hazardous tasks. This frees human workers to focus on more complex and creative aspects of their jobs.

→ Case Study: BMW’s Human-Robot Collaboration: BMW employs cobots in its factories. Cobots work alongside human workers, performing tasks such as lifting heavy objects. This reduces the risk of injury and enhances productivity.

Training and Skill Development: Human-AI collaboration extends beyond the factory floor. AI-driven training programs, often using virtual reality (VR) and augmented reality (AR), offer immersive learning experiences. These programs help workers acquire new skills efficiently, empowering them to adapt to evolving manufacturing technologies.

→ Case Study: Siemens’ AR Training: Siemens utilizes AR-based training to upskill workers. This technology helps new employees quickly become proficient in complex tasks, reducing training time by up to 60%.

Decision Support: AI serves as a valuable decision support tool for human workers. AI-driven analytics provide insights that inform decision-making, from supply chain optimization to production scheduling. Workers can make more informed choices, ultimately driving efficiency and productivity.

→ Case Study: Ford’s Supply Chain Optimization: Ford uses AI to optimize its supply chain. This has resulted in a 25% reduction in unplanned downtime and a 50% decrease in transportation costs.

Ethical Considerations: As AI becomes more integrated into manufacturing decision-making processes, ethical concerns, such as bias in algorithms, must be addressed. Companies must ensure that AI systems are designed and managed ethically, respecting the rights and well-being of their workforce.

→ Case Study: IBM’s Ethical AI: IBM has developed guidelines for ethical AI deployment. They prioritize fairness, transparency, and accountability in AI systems to ensure they benefit all stakeholders.

Manufacturers that embrace the trifecta of smart factories, AI-powered design, and human-AI collaboration gain a formidable competitive edge.

The Confluence of Smart Factories, AI-Enhanced Design, and Human-AI Interaction

The true power of AI in manufacturing emerges when these three pillars seamlessly intersect:

Efficiency Overdrive: Smart factories integrate AI-designed products into their production processes. Real-time optimization ensures that changes in product design or production requirements are rapidly accommodated. Human workers and AI systems evolve together, fostering a flexible and efficient manufacturing process.

Innovation Acceleration: AI-driven design innovation accelerates product development. By allowing AI to explore unconventional design solutions, companies can push the boundaries of what’s possible. The result is a portfolio of breakthrough products and solutions that redefine industry standards.

Human-Centric Technology: The synergy of human-AI collaboration is underpinned by a focus on human well-being and skill development. Workers are liberated from mundane tasks, allowing them to focus on creative problem-solving and higher-level responsibilities.

Competitive Advantage: Manufacturers that embrace the trifecta of smart factories, AI-powered design, and human-AI collaboration gain a formidable competitive edge. They deliver superior products, swiftly adapt to market changes, and optimize their operations. This positions them for success in an ever-evolving manufacturing landscape.

Conclusion

The future of manufacturing is not just a promise on the horizon; it is a dynamic and tangible reality. Driven by AI, smart factories, AI-driven design and prototyping, and the evolution of human-AI interaction and workforce development are the cornerstones of this transformation. Together, they are reshaping the manufacturing sector, making it more efficient, innovative, and adaptable than ever before.

The fusion of AI-driven efficiency, creative design innovation, and human-AI collaboration is not just a blueprint; it’s the very essence of the future of manufacturing. It’s an era where imagination meets reality, where machines and humans co-create, and where efficiency transcends conventional limits. Manufacturers that embrace this paradigm shift are poised for unparalleled success in the swiftly evolving landscape. The manufacturing industry’s future is unfolding today, and it’s nothing short of a thrilling revolution.